- Home

- Products

- Tube Mills / Pipe Making Machine

- RT32 HF Tube Mills

RT32 HF Tube Mills

This RT32 china automatic mild steel pipe making machine / pipe rolling mills is the new tube mills in 2018 especially for producing the automobile oil pipes and tubes.

- Model: RT32 (50.8mm×2.0mm)

The RT32 pipe rolling mill is intended for manufacturing of round/square pipe of Φ13mm-Φ50.8mm with Thickness of 0.6mm–2.0mm from cold-rolled, hot-rolled and galvanized coil strip.

- Features:

This RT32 automatic pipe production line is used to produce straight seam automatic oil pipes and tubes by means of steel slit strips with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal straight seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.

Finished product will be of round, square, rectangular pipe.

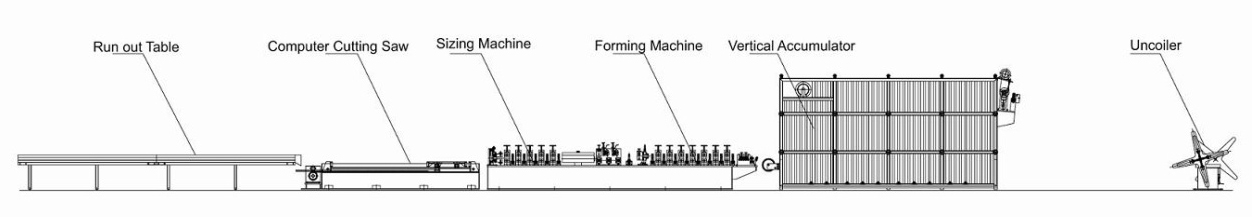

- Process Flow:

SLIT COIL ---- Un-coiler ----Storage/ Vertical accumulator ---- Forming ---- Welding ---- Cooling ---- Sizing ---- Cutting saw ---- Run out table ---- Finishing ---- Pipe collecting and packaging

- Technical Parameter for RT60 straight seam Tube Mills:

Specification:

1.1. INPUT

(1). Material: Low-carbon steel (Q195, Q235)

(2). Thickness: 0.6-2.0mm (SQ, REC Pipe: ≤1.5mm)

(3). Slit width: 40-160mm

(4). Coil Weight (Slit Coil): ≤1500 kg

(5). Coil ID: 350-450mm

(6). Coil OD: 800-1000mm

1.2. OUTPUT

(1). Round pipe dia.: 13-50.8mm

Wall thickness: 0.6-2.0mm

(2). Square Tube Size: 10×10-40×40mm

Wall thickness: δ≤1.5mm (SQ, REC Pipe)

(3). Length: 4-8meter (can be longer)

(4). To-length accuracy: ≤±3mm

1.3. LINE DATA

(1). Line Direction (optional): From Right to Left or from Left to Right(Viewed from operator side; will be double confirmed)

(2). Line Speed: 20-90/min

(3). Power for equipment motor: about 131.5KW

(4). Power for HF electric: 150KW (Solid State)

Machine Configuration:

(1) Double-side Un-coiler (Manual expansion)…………………………………………………………… 1 unit

(2) Vertical Accumulator………………………………………………………………….………….……..……… 1 unit

(3) Forming, Welding and Sizing mill…………………………………….……………………..…..………… 1 unit

A) Feeding & Leveling device

B) Forming machine

C) Guiding, Squeezing, Welding & Deburring device

D) One set of cooling water tank

E) Sizing mill

F) Main Driving System

(4) Computer-controlled Tracking Cutting Saw (Circular Saw Cutting) ………………………… 1 unit

(5) Finished Pipe Passing Conveyor (Run out table) ………………………………………………… 1 unit

(6) Solid State High Frequency Welder…………………………………………………………………..…… 1 unit

(7) Pneumatic System…………………………………………………….…………………………………………… 1 unit

(8) Electrical System with PLC Control and DC Drive Control System ..………..………………… 1 unit

Delivery time:

90~120 days

Shipping container:

2×40’HQ + 1×40’HQ

- Photos for Reference:

Double Side Uncoiler

Vertical Accumulator

Roll Forming Device

Welding And Scraping Device

Cooling Tank

Sizing Unit

Straightening Unit

Cold Cutting Saw Machine

- Product Applications:

- Tube Mills Word:

Model |

Diameter of Welded Tubes |

Wall Thickness of Round Tube |

Max. Size of Square Tube |

Max. Size of Rec. Tube |

Wall Thickness of Sq & Rec Tube |

Speed of Tube Welding |

Power of Major Motor |

High Frequency Power |

RT16 |

8-25mm |

0.3-1.0mm |

20x20mm |

12.7x25.4mm |

0.3-0.8mm |

30-110m/min |

37KW |

100KW |

RT25 |

8-32mm |

0.4-1.3mm |

25x25mm |

20x30mm |

0.4-1.0mm |

30-110m/min |

45KW |

100KW |

RT25 |

8-32mm |

0.4-1.3mm |

25x25mm |

20x30mm |

0.4-1.0mm |

30-130m/min |

55KW |

150KW |

RT32 |

10-40mm |

0.5-1.8mm |

30x30mm |

20x40mm |

0.5-1.4mm |

30-100m/min |

90KW |

150KW |

RT32 |

13-40mm |

0.5-1.8mm |

30x30mm |

20x40mm |

0.5-1.4mm |

30-130m/min |

132KW |

150KW |

RT45 |

13-50.8mm |

0.6-2.3mm |

40x40mm |

30x50mm |

0.6-1.7mm |

30-100m/min |

110KW |

150KW |

RT45 |

13-50.8mm |

0.6-2.0mm |

40x40mm |

30x50mm |

0.6-1.5mm |

30-130m/min |

160KW |

150KW |

RT50 |

19-63.5mm |

0.7-2.75mm |

50x50mm |

40x60mm |

0.7-2.2mm |

30-100m/min |

160KW |

200KW |

RT50 |

19-63.5mm |

0.7-2.5mm |

50x50mm |

40x60mm |

0.7-2.0mm |

30-130m/min |

220KW |

200KW |

RT50 to 76 |

19-76mm |

0.7-2.75mm |

60x60mm |

40x80mm |

0.7-2.2mm |

30-100m/min |

160KW |

200KW |

RT50 to 76 High speed |

19-76mm |

0.7-2. 5mm |

60x60mm |

40x80mm |

0.7-2.0mm |

30-130m/min |

220KW |

200KW |

RT60 |

19-63.5mm |

0.8-3.5mm |

50x50mm |

40x60mm |

0.8-2.7mm |

30-90m/min |

185KW |

250KW |

RT60 |

19-63.5mm |

0.8-3.0mm |

50x50mm |

40x60mm |

0.8-2.5mm |

30-120m/min |

250KW |

300KW |

RT60 to 76 |

19-76mm |

0.8-3.5mm |

60x60mm |

40x80mm |

0.8-2.7mm |

30-90m/min |

200KW |

250KW |

RT60 to 76 High speed |

19-76mm |

1.0-3.0mm |

60x60mm |

40x80mm |

0.8-2.5mm |

30-120m/min |

250KW |

300KW |

RT60 |

22-100mm |

1.0-3.0mm |

76.2x76.2mm |

50.8x101.6mm |

1.0-2.5mm |

30-80m/min |

200KW |

250KW |

RT76 |

25-90mm |

1.0-4.0mm |

70x70mm |

60x80mm |

1.0-3.2mm |

30-70m/min |

110KWx2 |

300KW |

RT76 |

25-90mm |

1.0-4.0mm |

70x70mm |

60x80mm |

1.0-3.2mm |

30-100m/min |

160KWx2 |

400KW |

RT76 to 127 |

32-127mm |

1.2-4.0mm |

100x100mm |

80x120mm |

1.2-3.0mm |

30-70m/min |

110KWx2 |

300KW |

RT90 |

32-127mm |

1.5-4.5mm |

100x100mm |

80x120mm |

1.5-3.5mm |

20-60m/min |

132KWx2 |

400KW |

RT90 to 140 |

32-140mm |

1.5-4.5mm |

110x110mm |

100x120mm |

1.5-3.5mm |

20-60m/min |

132KWx2 |

400KW |

RT115 |

48-127mm |

1.5-5.0mm |

100x100mm |

80x120mm |

1.5-4.0mm |

20-60m/min |

160KWx2 |

400KW |

RT115 |

48-140mm |

1.5-5.0mm |

110x110mm |

100x120mm |

1.5-4.0mm |

20-60m/min |

160KWx2 |

400KW |

RT115 |

48-165mm |

1.8-5.0mm |

130x130mm |

120x140mm |

1.8-4.0mm |

20-60m/min |

160KWx2 |

400KW |

RT165 |

50.8-165mm |

2.0-6.0mm |

130x130mm |

120x140mm |

2.0-5.0mm |

15-50m/min |

200KWx2 |

500KW |

RT165 |

76-219mm |

2.0-6.0mm |

170x170mm |

140x200mm |

2.0-5.0mm |

15-45m/min |

200KWx2 |

500KW |

RT219 |

89-219mm |

2.5-8.0mm |

170x170mm |

140x200mm |

2.5-6.0mm |

12-35/min |

220KWx2 |

600KW |

RT273 |

102-273mm |

2.5-10.0mm |

210x210mm |

180x240mm |

2.5-8.0mm |

10-30m/min |

250KWx2 |

800KW |

RT355 |

219-355mm |

4.0-12.0mm |

280x280mm |

260x300mm |

4.0-10.0mm |

10-30m/min |

250KWx2 |

1200KW |

- Product Tube Mills / Pipe Making Machine Stop-cut Rollformer / Roll Forming Line Fly Cutting Roll Former Line Slitting Lines Cut to Length Lines Auxiliary Equipment

- Contact Us Office Address: No.12, Zhongba RD(S), Hai´an, Nantong, Jiangsu, China Tel: +86 513 889 02466 Mobile/WhatsApp/Wechat: +86 13506296101 Email: offer@reliantt.com

- About Us NANTONG RELIANTT Machinery Co., Ltd. as a member of RLT group, engaged in manufacturing and exporting roll forming machine, tube mills, cut to length line, slitting line, shear and press brake etc for more than 20 years.