- Home

- Products

- Tube Mills / Pipe Making Machine

- HF Directly To Rectangle, Square Tube Line

HF Directly To Rectangle, Square Tube Line

- Features:

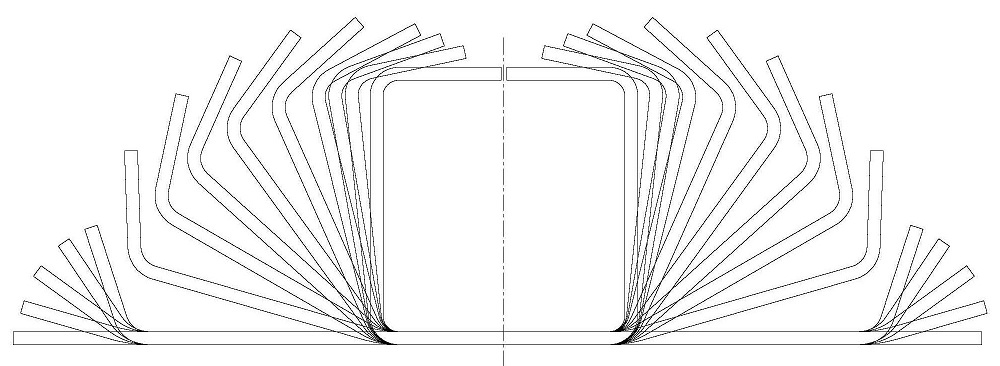

Square & Rectangle pipe mill is the special equipment to produce square and rectangle steel pipe. This equipment adopts the multipoint bending combined-type forming technology. One set of mould can produce all size of square and rectangle pipe. Compared with the traditional technology, the produce will have a good appearance, a good angle; share one set of mould, can cut down the cost of the machine, shorten the time of adjusting the mould; decrease the forming resistance, lighten the mould wear, reduce the load of power utilization.

- Process Flow:

Raw Material (Strip Coil) ---- Decoiler ---- Snubber Roller + Pinch Roll + Leveler ---- Shear & Butt Welder ---- Horizontal Accumulator ---- Forming (directly forming to square to rectangle shape) ---- HF Welding ---- Scraping ---- Cooling ---- Sizing ---- Straightening ---- Cutting ---- Run-out

Decoiler, Leveler

Horizontal Accumulator

Roll Forming

Rollers Squeezing

Sizing

Milling Cutting Saw

Tube Mill Technical Specification - directly square to square (Reliantt)

Model |

Raw material:бb≤580Mpa, бs≤350Mpa |

Forming Speed |

|||

|

Specifications of Square& Rec. Pipe |

Specifications of Round Pipe |

|

||

|

Diameter range(mm) |

Thickness range(mm) |

Diameter range(mm) |

Thickness range(mm) |

|

RT100×5 |

40×40~100×100 |

2.0~5.0 |

Ф50~Ф140 |

2.0~5.0 |

10~60 |

RT160×6 |

60×60~160×160 |

2.0~6.0 |

Ф60~Ф165 |

2.0~6.0 |

10~50 |

RT200×8 |

80×80~200×200 |

3.0~8.0 |

Ф108~Ф219 |

3.0~8.0 |

10~35 |

RT250×10 |

100×100~250×250 |

3.0~10.0 |

Ф114~Ф273 |

3.0~10.0 |

10~35 |

RT300×12.7 |

150×150~300×300 |

4.0~12.7 |

Ф165~Ф377 |

4.0~12.7 |

6~30 |

RT400×16 |

200×200~400×400 |

6.0~16.0 |

Ф219~Ф508 |

6.0~16.0 |

6~20 |

RT500×18 |

300×300~500×500 |

8.0~18.0 |

Ф325~Ф610 |

8.0~18.0 |

6~20 |

- Product Tube Mills / Pipe Making Machine Stop-cut Rollformer / Roll Forming Line Fly Cutting Roll Former Line Slitting Lines Cut to Length Lines Auxiliary Equipment

- Contact Us Office Address: No.12, Zhongba RD(S), Hai´an, Nantong, Jiangsu, China Tel: +86 513 889 02466 Mobile/WhatsApp/Wechat: +86 13506296101 Email: offer@reliantt.com

- About Us NANTONG RELIANTT Machinery Co., Ltd. as a member of RLT group, engaged in manufacturing and exporting roll forming machine, tube mills, cut to length line, slitting line, shear and press brake etc for more than 20 years.