- Home

- Products

- Tube Mills / Pipe Making Machine

- Stainless Steel Pipe Mill Machine

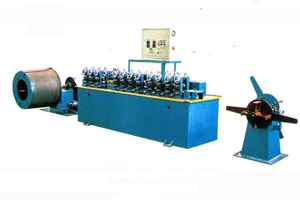

Stainless Steel Pipe Mill Machine

RTS Stainless Steel Pipe Mill Line

Name: Stainless Steel Pipe Mill Machine

Model: RTS Stainless Steel Pipe Mill Line

We can also supply the customized machines.

- Features:

Stainless steel pipe making machine is designed for manufacturing stainless steel straight welded pipe for metallurgy, construction, transportation, and machinery and vehicle industries. It adopts long steel strip as the material to manufacture steel pipes according to requested size by cold rolled forming and argon arc welding method. To be specific, the stainless steel pipe production line can produce round pipe, square and rectangular tube, as well as section steel through cold rolled forming and TIG welding technology.

The machine is designed featuring easy and safe to operate, low maintenance, and cost reduction, reducing and high production. The stainless steel pipe, which allows flatting, forming, welding, annealing, polishing, sizing, straightening, finishing, cutting, and unloading at one time for production.

- Applications:

1. Industrial Steel Pipes |

2. Decoration Pipe |

- Process Flow:

Slit Coil ---- Un-Coiler ---- Forming ---- TIG Welding ---- De-beading ---- Grinding ---- Sizing ---- Annealing ---- Sizing ---- Cutting ---- Run Out Table ---- Pipe Collecting And Packaging

- Machine Configurations:

1. Uncoiler |

2. Forming Section |

3. TIG Welder |

4. Electric Control Panel |

5. Welding Torch Stand |

6. De-beading Section |

7. Seam Grinding |

8. Initial Sizing |

9. Online Bright Annealing |

10. Final Sizing |

11. Cutting Sation |

12. Run Out Table |

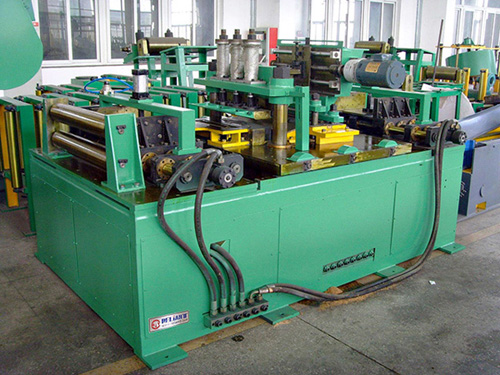

1. Stainless Steel Tube Mill

Industry Tube Mill and Decoration Tube Mill can be provided. Unique design, provided with rational structure. Twice heat treatment (quenching & HF) for horizontal shafts, good quality casting via CNC machining. The machine is consist of heavy platform, accurate roller stands, XY or XYZ welding torch stand and SS made seam grinding cases. Siemens brand electrical elements mainly used, PLC and touch screen are also available. Online heat treatment & de-beading system can be connected with tube mill.

Industry SS Tube Mill - Online de-beading - Online Bright Annealing

Large Diameter Tube Mill

Titanium Tube & 8 Series SS Tube Mill

Industry SS Tube Mill ( Qucik Roller Changeover Platform)

Capillarty Tube Mill

A. Parameters of Industry Tube Mill

Title |

GRTS30 |

GRTS40 |

GRTS50 |

GRTS60 |

GRTS80 |

GRTS100 |

GRTS110 |

OD (mm) |

Φ5-20 |

Φ8-45 |

Φ25-Φ76 |

Φ50.8-Φ114 |

Φ89-Φ159 |

Φ114-Φ219 |

Φ114-Φ325 |

WT (mm) |

δ0.3-δ1.2 |

δ0.3-δ2.5 |

δ0.5-δ3 |

δ0.6-δ3.5 |

δ1-δ4 |

δ1.5-δ5 |

δ1.5-δ8 |

Speed (m/min) |

2-9 |

0.6-6 |

0.6-4 |

0.6-4 |

0.5-3 |

0.5-2 |

0.4-1.6 |

Frequency Conversion Driving Motor (kw) |

4kw |

7.5+5.5 |

11+7.5 |

15+11 |

18.5+15 |

22+15 |

22+18.5 |

Seam Grinding Unit |

3kwx 1 |

3kw x N |

3kw x N |

3kw x N |

3kw x N |

3kw x N |

3kw x N |

Transmission |

Gear Box |

Gear Box |

Gear Box |

Gear Box |

Gear Box |

Gear Box |

Gear Box |

M/C Length (m) |

5 |

7.8 |

8.5 |

9 |

13 |

14 |

17 |

Remark: |

A, Extra order of online de-beading & heat treatment system is available; B, Vertical or horizontal type decoiler is available; C, Abrasive wheel cutting (fast rotation) or saw blade (slow rotation with water cooling, oil & air mixed) cutting or saw cutting is available; D, Cutting sta. or rolling system is available for RTS20; E, Strengthened type or synchronization type roller stands is available. F, Extra order of TIG (argon arc) welder or plasma welder is available; G, Special design in term of client's requirement is available. |

||||||

B. Parameters of Decoration Tube Mill

Title |

RTS20 |

SRTS40 |

RTS40 |

RTS50 |

RTS60 |

OD (mm) |

Φ4~Φ15 |

Φ6~Φ32 |

Φ8~Φ48 |

Φ38~Φ76 |

Φ50.8~Φ114 |

WT (mm) |

δ0.2~δ0.8 |

δ0.17~δ1.2 |

δ0.18~δ2 |

δ0.4~δ2.5 |

δ0.5~δ3 |

Speed (m/min) |

2~12 |

2~15 |

2~15 |

3~12 |

3~10 |

Driving Motor (kw) |

3 |

5.5 |

7.5 |

11 |

15 |

Seam Grinding Unit |

N/A |

3kw x N |

3kw x N |

3kw x N |

3kw x N |

Transmission |

Gear Box |

Worm Gear Box |

Worm Gear Box |

Worm Gear Box |

Worm Gear Box |

M/C Length (m) |

2.4 |

6 |

6.5 |

7.5 |

8.5 |

Remark: |

A, Special design in term of client's requirement is available; B, Vertical or horizontal type decoiler is available; C, Abrasive wheel cutting (fast rotation) or saw blade (slow rotation with water cooling, oil & air mixed) cutting or saw cutting is available; D, Auto cutting or rolling system is available on RTS20; E, Frequency conversion or speed adjustable motor is available for driving power; F, Extra order of TIG (argon arc) welder or plasma welder is available. |

||||

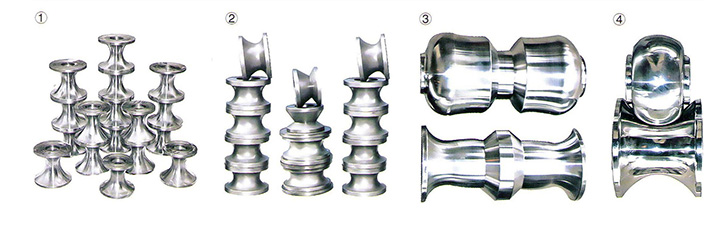

2. Roller

Selection of high quality roller steel Cr12MoV or copper alloy TS4 as the material, designed via Pro-E and AutoCAD, CNC machining. Steel Cr12Mov has advantage of high wear resistance, strong toughness, and high hardness, great hardenability, widely used in SS industry. Manufacture procedure: material ---- cutting machine ---- drilling machine ---- machining tool ---- initial CNC machining tool ---- grinding machine ---- heat treatment in vacuum ---- hardness test ---- grinding inside and out-side ---- final CNC machining tool. Hardness HRC HRC61~63. Copper alloy TS4 widely used in titanium and high class stain-less steel industry, it has the advantages of good wear-resisting, higher hardness HRC38 45, lowest hurt of tube surface compare to normal steel.

M/C |

Standard Round (mm) |

Standard Square (mm) |

M/C |

Standard Round (mm) |

Standard Square (mm) |

|

RTS20 |

Φ3-Φ15 |

|

RTS60 |

RTS50 |

Φ50.8 |

40 x 40 25 x 25 |

RTS40 |

Φ6, Φ8, Φ9.5, Φ12.7 |

|

Φ63.5 |

50 x 50 |

||

Φ15.9, Φ9.5, Φ22.2 |

|

Φ76.2 |

60 x 60 45 x 75 |

|||

Φ25.4 |

19 x 19 20 x 20 25 x 13 |

RTS80 |

Φ88.9 |

45 x 95 |

||

Φ31.8 |

25 x 25 |

Φ101.6 |

|

|||

Φ38.1 |

30 x 30 25 x 38 |

|

Φ114.2 |

|

||

Φ127 |

|

|||||

Φ159 |

|

|||||

Φ50.8 |

40 x 40 |

RTS100 |

Φ219 |

|

||

25 x 25 |

RTS110 |

Φ325 |

|

|||

Remark |

Only standard sizes listed, please notice the special sizes. |

|||||

3. Online De-beading System & Bright Annealing System

Online De-beading System

Treating the welded tube seam online, rolling the outer & inner seam synchronously, Strengthen the advantage of welded tube due to smooth seam. System are automatically controlled by PLC system & proportional hydraulic valve. There are advantage of stable working performance, high yield and easy installation. It is becoming a neces-sary section of high-end tube mill.

Model |

Size(mm) |

Driving Power (kw) |

QZ40 |

Φ16~Φ38.1 |

11 |

QZ50 |

Φ19~Φ63.5 |

15 |

QZ60 |

Φ38~Φ101 |

18.5 |

QZ90 |

Φ114~Φ219 |

22 |

Online Bright Annealing System

Solid super audio frequency induction heating power supply & at-mosphere protection cooling complete equipment is mainly used for heating & cooling for stainless steel tubes, thus achieving the purpose of bright solid solution. This equipment adopts the method of induc-tion heating, & the tubing moves along the axis through the induction heating coil with its temperature heated to 1000 to 1100, & continues to move through the cooling water jacket with its temperature lowered rapidly, when it arrives at the exit of the water jacket, its temperature will be below 100. The heating and the cooling are completed under the protective atmosphere, thus ensuring the brightness of tube walls.

Model |

Size(mm) |

Driving Power(kw) |

BAS40 |

Φ6~Φ32 |

60 |

BA40 |

Φ8~Φ50.8 |

100 |

BA50 |

Φ19~Φ63 |

100 |

BA60 |

Φ25~Φ76 |

120 |

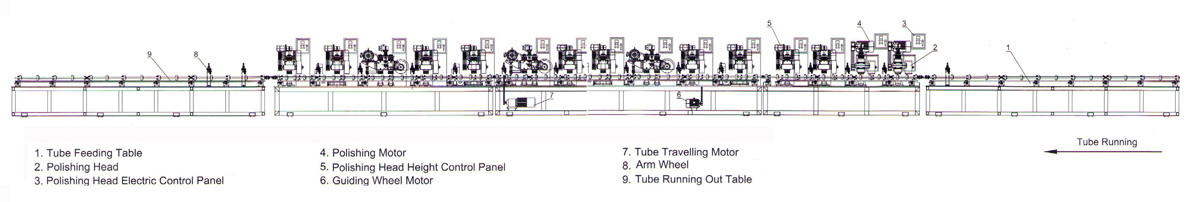

4. Polishing Machine Line

- Product Tube Mills / Pipe Making Machine Stop-cut Rollformer / Roll Forming Line Fly Cutting Roll Former Line Slitting Lines Cut to Length Lines Auxiliary Equipment

- Contact Us Office Address: No.12, Zhongba RD(S), Hai´an, Nantong, Jiangsu, China Tel: +86 513 889 02466 Mobile/WhatsApp/Wechat: +86 13506296101 Email: offer@reliantt.com

- About Us NANTONG RELIANTT Machinery Co., Ltd. as a member of RLT group, engaged in manufacturing and exporting roll forming machine, tube mills, cut to length line, slitting line, shear and press brake etc for more than 20 years.