- Home

- Products

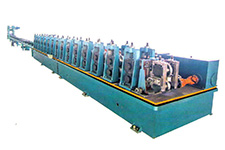

- Tube Mills / Pipe Making Machine

- Stainless Steel Pipe Mill Machine

Stainless Steel Pipe Mill Machine

Auto Round Tube Polishing Process Flow:

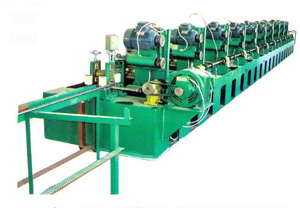

Automatic Square Tube Polishing Machine

Automatic Online Square Tube Polishing Machine

Square Tube (Flat bar) Polishing Machine

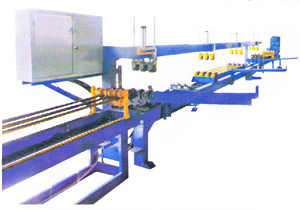

Round Tube Inside Polishing Machine

Coil Polishing Machine

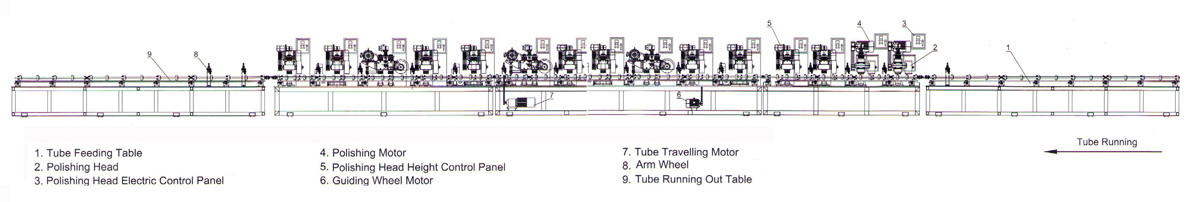

A. Auto Round Tube (Bar) Polishing Machine Line - Horizontal Type

Type |

Mechanical Type |

Manual Type |

Universal Shaft Transmission |

Short Tube (Short Round Bar) |

|||||

(Small) |

(Middle) |

(Large) |

(Small) |

(Middle) |

(Large)

|

||||

Tube OD (mm) |

Angle Iron Table |

Φ3-Φ12 |

Φ8-Φ63 |

N/A |

Φ3-Φ12 |

Φ8-Φ63 |

N/A |

N/A |

Φ6-Φ76 |

Roller Table |

N/A |

Φ8-Φ89 |

Φ25-Φ127 |

N/A |

Φ8-Φ89 |

Φ25-Φ127 |

Φ12-Φ76 |

N/A |

|

Bar OD (mm) |

Angle Iron Table |

Φ3-Φ8 |

Φ6-Φ25 |

N/A |

Φ3-Φ8 |

Φ6-Φ25 |

N/A |

N/A |

Φ6-Φ40 |

Roller Table |

N/A |

Φ6-Φ50 |

Φ12-Φ60 |

N/A |

Φ6-Φ50 |

N/A |

Φ10-Φ50 |

N/A |

|

Power(Kw)x N |

2.2/3 |

4 |

5.5 |

2.2/3 |

4 |

5.5 |

4 |

4 |

|

Speed Conversion Walking Motor(mm) |

1.5 |

3 |

4 |

1.5 |

3 |

4 |

3 |

3 |

|

Polishing Wheel Size (mm) |

Φ170-3 00 |

Φ170-300 |

Φ170-350 |

Φ170-300 |

Φ70-300 |

Φ170-350 |

Φ170-350 |

Φ170-300 |

|

Heads Gap Distance(mm) |

460 |

560 |

600 |

460 |

560 |

600 |

630 |

480 |

|

M/C Width (mm) |

900 |

1100 |

1300 |

900 |

1100 |

1300 |

1100 |

1100 |

|

Remark: |

M/C Length = Polishing heads gap distance x N (Polishing heads Qty), Feeding + blanking tables = 6m + 6m (regular type). Manual or auto feeding for options, plus auto blanking. Dry & wet polishing for options. Dust collection pipe & tank is extra, water spray (wet) or hop-pocket (dry) type for options. Polishing speed set via walking motor and guiding wheel angle (α). |

||||||||

B. Auto Round Tube (Bar) Polishing Machine Line - Vertical Type

Model |

Auto Round Tube (Bar) Polishing Machine Line - Vertical Type (Extra Large) |

Auto Round Tube (Bar) Polishing Machine Line - Vertical Type (Large) |

Auto Round Tube (Bar) Polishing Machine Line - Vertical Type (Small) |

OD (mm) |

(Bar):Φ30-Φ100 (Thickness WT):Φ150-Φ530 |

(Bar):Φ20-Φ80 (Thickness WT): Φ50-Φ300 |

(Bar): Φ20-Φ50 (Thickness WT): Φ30-Φ89 |

Speed (m/min) |

1~4 |

1~6 |

1~15 |

Power(kw) |

7.5(or11)xN |

5.5(or7.5) x N |

4xN |

Remark |

Suitable for extra large OD & extra heavy WT pipe & bar polishing as well as rust removing, PLC controlling & electrical operation, arm wheels with power. |

Suitable for large OD & heavy WT pipe & bar polishing as well as rust removing, PLC controlling & electrical operation. |

Suitable for middle OD but heavy pipe & bar polishing as well as rust removing, Auto & semi-auto operation are available. |

C. Auto Abrsive Belt Polishing Machine - Round Tube

Title |

Size (mm) |

Speed (m/mm) |

Power (kw) |

Transmission |

Electrical Control |

Belt Auto Avoiding System |

Water Cooling System |

Abrasive Belt Size (mm) |

M/C Size (mm) |

Weight (kg) |

Parameter |

Φ15-219 |

1-12 |

7.5xN |

Polyurethane Guiding Wheel |

PLC |

Yes |

Yes |

3000 x150 |

4500 X1250 x2200 |

2000kg/he ad |

D. Square (Rectangle) Tube/Flat Bar Polshing Machine

Model |

Normal Type |

Large Type |

Heavy Type |

|||

Size (mm) |

10x10-80x80 |

32Head Machine 10350 x1200mm 9000 kg |

10x10-100x100 |

32Head Machine 10800x1200mm 10500kg |

10x10-150x150 |

32Head Machine 12000x1600mm 18000kg |

Speed (m/min) |

2-20 |

2-20 |

2-20 |

|||

Power (kw) |

3xN (32 Head) |

4xN (32 Head) |

5.5xN (32 Head) |

|||

Transmission |

Worm Gear Box |

Worm Gear Box |

Worm Gear Box |

|||

Shaft OD (mm) |

Φ25.4/Φ31.8 |

28Head Machine 9100x1200mm 8000 kg |

Φ25.4/Φ31.8 |

28Head Machine 9100x1200mm 9500kg |

Φ25.4/Φ31.8 |

28Head Machine 11200x1600mm 16000kg |

Traveling |

3 |

4 |

5 |

|||

Motor(kw) |

|

|

|

|||

E. Coil & Flat Bar Polishing Machine Line

Model |

250 Coil Polishing Machine (Double) |

400 Coil Polishing Machine (Double) |

700 Coil Polishing Machine (Double) |

Size(mm) |

200 x 0.2 |

350 x 0.2 |

650 x 0.5 |

Speed (m/min) |

1-15 |

1-15 |

1-15 |

Power(kw) |

4x N |

7.5 x N |

11/(or15)xN |

Transmission |

Rolling System (option) |

Rolling System (option) |

Rolling System (option) |

Remark |

Forward (suitable for wide strip, “S” polishing) or drawing type transmission, mirror polishing, oxide layer treatment after hot rolling |

||

5. Straightening Machine

Technical imported from Germany in order to remove internal stress to ensure the pipe straightness accuracy.

Type |

Double Curve JZ25 |

Double Curve JZ38 |

Double Curve JZ76 |

Special 13 Rollers |

Size |

8-25 |

10-38 |

16-76 |

16-102 |

WT (mm) |

0.3-1.5 |

0.3-1.2 |

0.3-1.2 |

4 |

Power (kw) |

1.5x2 nos. |

3x2 nos. |

4x2 nos. |

3 |

Driven Roller (nos.) |

6 |

6 |

6 |

7 |

Remark |

Cr12MoV (Same as SKD11) or Nylon material are available for rollers. |

|||

6. Cold Forming Mill

Precision forming for special section, hydraulic pressure punching & air cylinder cutting. Widely used in the industry of automobile, electric apparatus, solar energy and so on. The design will be according to various requirements.

Cold Forming Machine

Cold Forming Mill (Online Hydraulic Punch Cutting)

Cold Forming Mill (Online Hydraulic Punching & Cutting)

7. Water Pressure Testing Machine

Water pressure testing machine widely used in industry tube area to instead of seamless tube.

Water Pressure Testing Machine

Title |

Introduction Title |

Title |

Introduction |

Test Qty |

Single Tube |

Seal |

End Seal |

Tube |

Round |

Control |

PLC Control |

Pressure Range |

1~16Mpa

|

Operation |

Auto and Manual

|

Max Pressure Maintaining |

14Mpa |

Tube OD |

Φ8~Φ114mm |

8. Assistant Machine

Saw Cutting System

Plasma Cutting System

Short Length Tube Cutting System with Double Heads

Hydraulic Vertical Type Cutting System

Servo Control Flying Cutting System

Thread Making Machine

Auto Strip Cutting-welding Machine

Abrasive Belt Seam Grinding System

Online Eddy Current System

- Product Tube Mills / Pipe Making Machine Stop-cut Rollformer / Roll Forming Line Fly Cutting Roll Former Line Slitting Lines Cut to Length Lines Auxiliary Equipment

- Contact Us Office Address: No.12, Zhongba RD(S), Hai´an, Nantong, Jiangsu, China Tel: +86 513 889 02466 Mobile/WhatsApp/Wechat: +86 13506296101 Email: offer@reliantt.com

- About Us NANTONG RELIANTT Machinery Co., Ltd. as a member of RLT group, engaged in manufacturing and exporting roll forming machine, tube mills, cut to length line, slitting line, shear and press brake etc for more than 20 years.