Features:

We can supply the rolls (together with the spacers, clamps, and sample plate) for the tube mills or for roll forming machines for the customers if get the drawings of the rolls. With our abundant experience and mature technology, we can also make the drawing according to some parameter information of the machine.

Machining Process of Rolls:

(1) Raw material preparation – forge piece: inconel

(2) Semi-finishing; Numerical control cutting machining

(3) Numerical control finishing machining

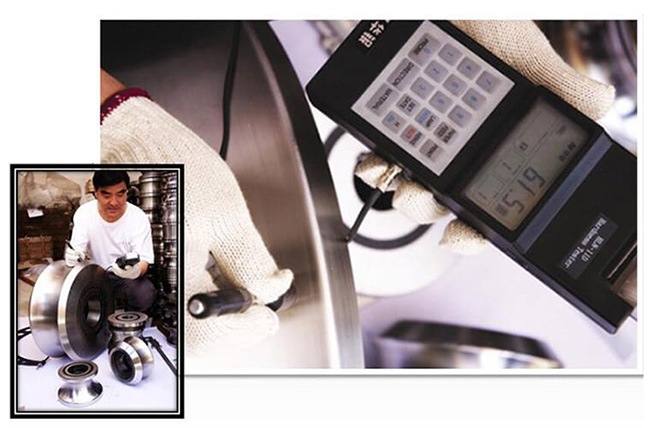

(4) Product inspection – dimensions, form and position tolerance

(5) Product inspection – hardness

(6) Customer inspection

(7) Finished-parts storage – shipshape

(8) Packing

Roll Material:

| Designation | Chemical Composition (%) | |||||||||

| China | USA | Japan | C | Si | Mn | Cr | Mo | V | P | S |

| Cr12Mo1V1 | D2 | SKD11 | 1.45~1.70 | ≤0.40 | ≤0.40 | 11.00~12.50 | 0.40~0.60 | 0.15~0.30 | ≤0.030 | ≤0.030 |

| Cr12 | D3 | SKD1 | 2.00~2.30 | ≤0.40 | ≤0.40 | 11.00~13.00 | - | - | ≤0.030 | ≤0.030 |

| GCr15 | S2100 | SUJ2 | 0.95~1.05 | 0.15~0.35 | 0.25~0.45 | 1.40~1.65 | - | - | ≤0.025 | ≤0.025 |