Features:

Downpipe / Rainspout Roll Forming Line, can produce round & square downpipe / rainspout, equip with elbow machine.

1. Bending precision: the maximum profile deviations (dimensions and shape) shall not exceed the tolerances specified as following data (or equivalent tolerances).

2. Bending quality: ability to bend the profiles of the specified configuration at the specified maximum steel thickness; cracking of the steel or metal coating is not permitted for all required steel grades.

3. Maximum production speed: 0-15 meters per minute.

We are not only offer customers a wonderful gutter roll forming machine for making, but also the abundant experience, precision making, stable automatic manufacture by hydraulic power, hi-tech control system, and our enthusiasm.

Applications:

The products produced by the downpipe & gutter roll forming line is widely used in factory, workshop, garage, warehouse, locomotive shed, hanger, exhibition building, cinema, theatre, stadium, garden etc.

Process Flow:

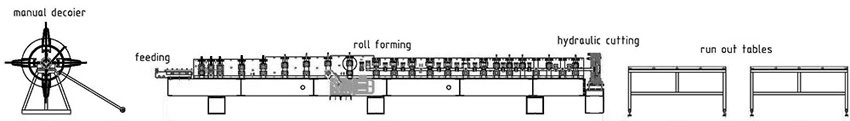

Uncoiler --- Feeding --- Roll Forming --- Cutting --- Exit Rack

Profile Drawings for Reference:

Photos for Reference: