Features:

NEW (0.5-3.0) × 1600 stainless steel decoiling, leveling and cutting to length line machine with edge trimming and scrap recoiling device.

This equipment is used for processing the steel coil into the desired length steel sheet and stacking them in order through decoiling, leveling, measuring and shearing.

Stainless Steel Cut to Length Line:

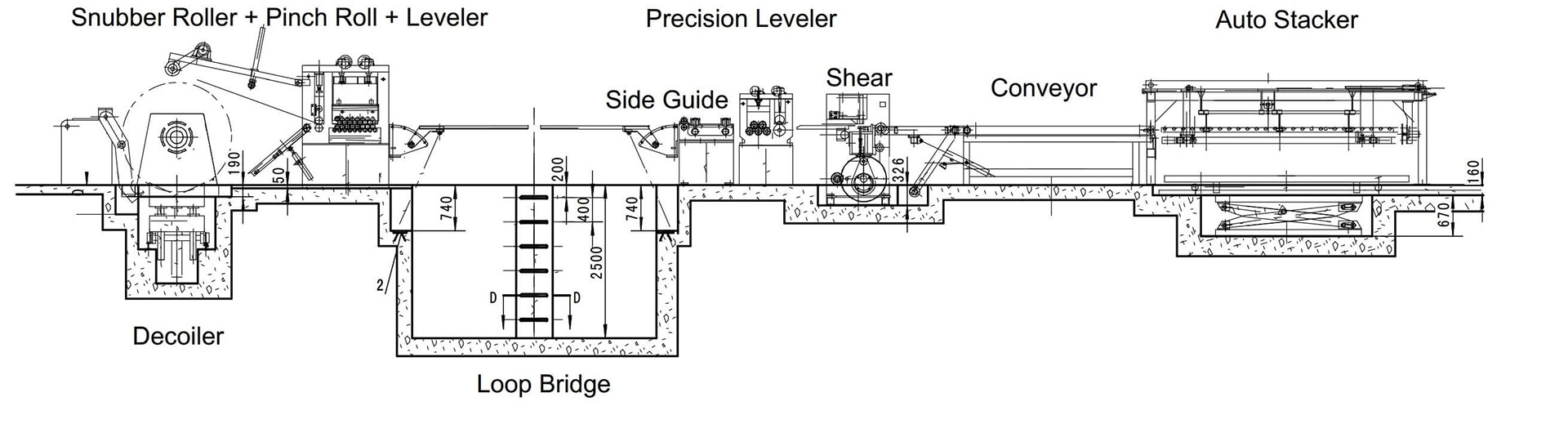

Cut-to-length, also know as a blanking line or CTL, mainly composed of the decoiler, pinch roll and leveler, length controller, shearer and stacker etc., accompany of the feeder, side guider, conveyor etc.

We can Supply High Speed Metal Coil Cut to Length Machine with the max. speed is 80m/min. And we can supply the low speed 24m/min one for 0.3-3.0mm thickness.

Process Flow for Cut to Length Line:

Paper recoiler ---- Coil Lifter ---- Decoiler ---- Snubber Roller + Pinch Roll + 6-HI 21-roller Leveling Machine ---- Loop Bridge ---- Side Guide---- (options: edge trimming ---- scrap recoiler ---- loop bridge ---- side guide )---- Precision 5-roller Leveling Machine(import servo control) + Film-on Device ---- Shear ---- conveyor ---- Auto stacker (4 m) + X Lifting Platform + Unload Cart

Technical Parameter for Decoiling and Leveling Line:

Input

| Coil Material | Stainless steel |

| Material Thickness | 0.5~3mm |

| Material Width | 600~1500mm |

| Coil I.D. | Φ508/610mm (add cushion cover in 610mm) |

| Coil O.D. | Φ2000mm |

| Coil Weight | 15T |

Output

| Material Thickness | 0.5~3mm |

| Material Width | 600~1500mm |

| Leveling Tolerance | ≤±1.5mm/m2 (as 1.5mm thickness) |

| Cutting Tolerance | length: ≤±0.5mm (per 2000mm length sheet) Diagonal: ≤±1.0mm (per 2000mm×1600mm sheet) |

| Cutting Length | 500mm~4000mm |

Line Data

| Leveling Speed | 5~60m/min (adjustable) |

| Line Speed | 15~22 pcs/min (as per 2000mm length sheet) 26~30 pcs/min (as per 1000mm length sheet) 35~40 pcs/min (as per 500mm length sheet) |

| Total Power | Appro. 140kW |

| Total Space | Appro. 30m×7m (L×W) |

| Line Direction | From left to right (will be double confirmed) |

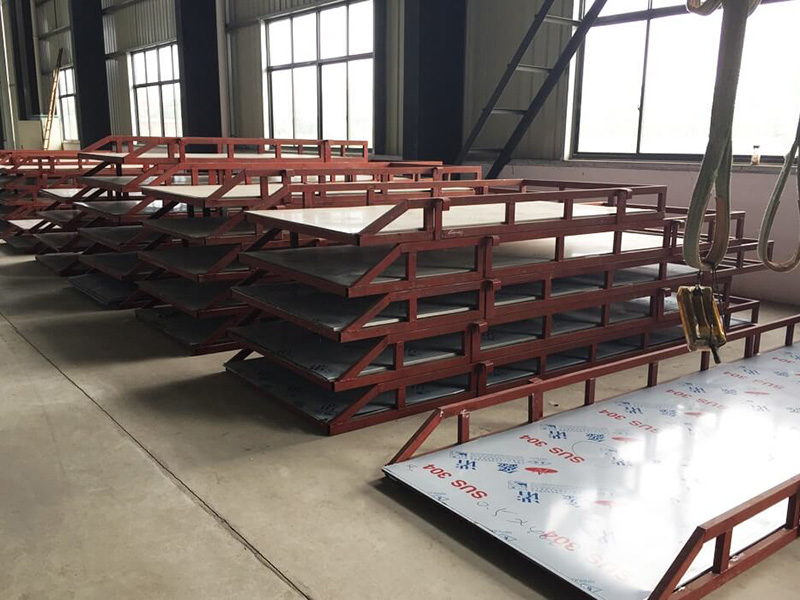

Photos for Reference: