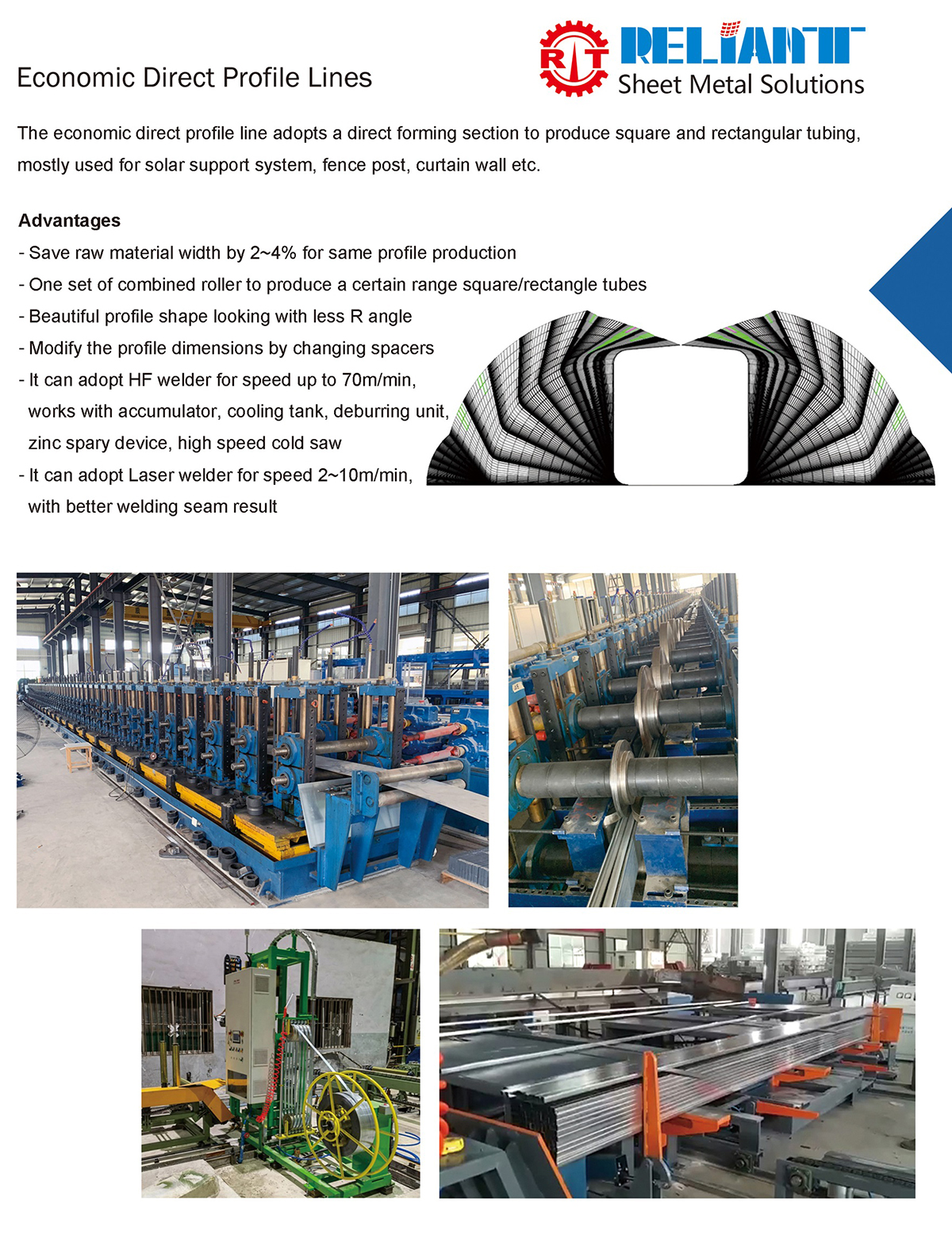

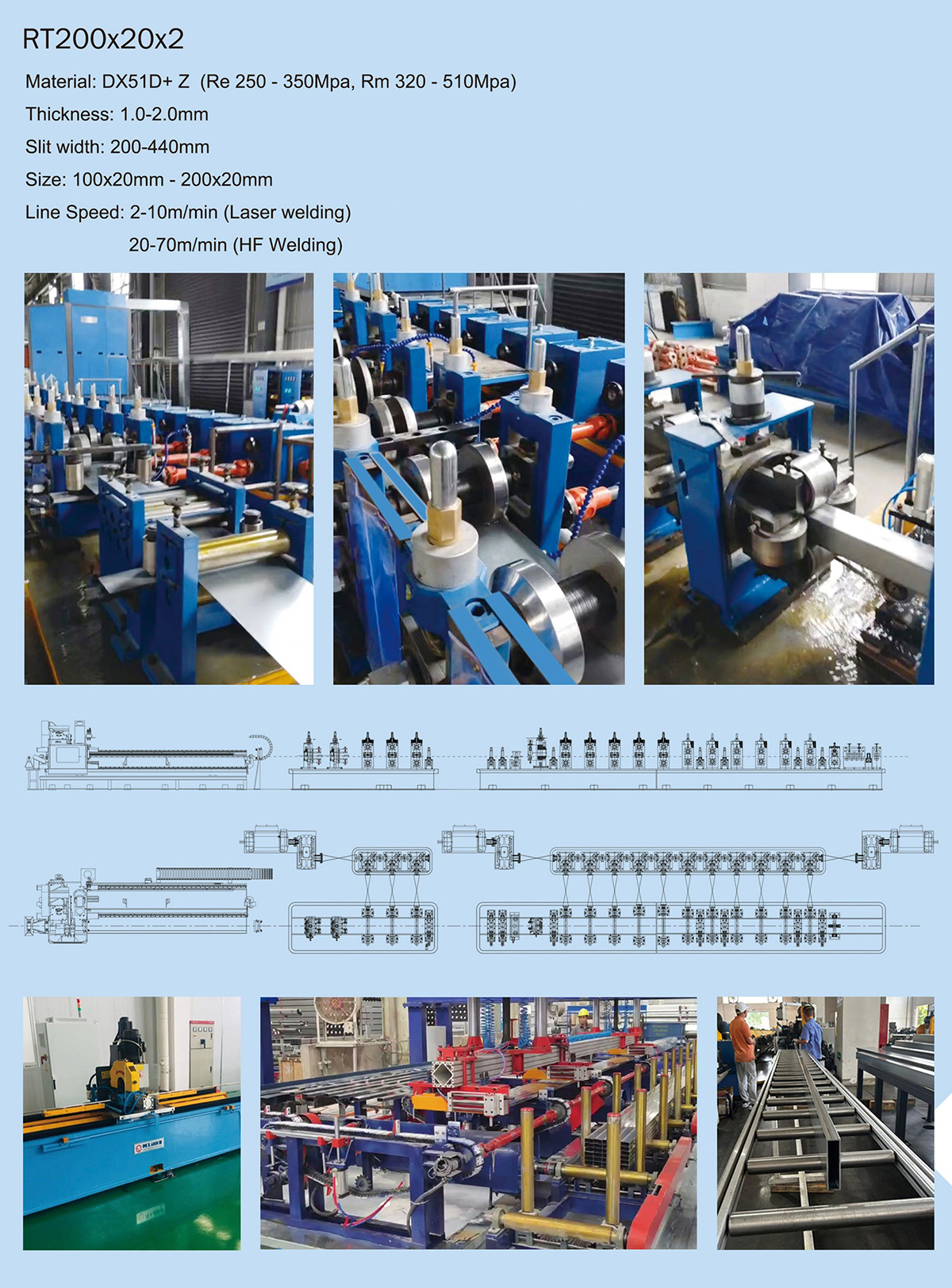

Features:

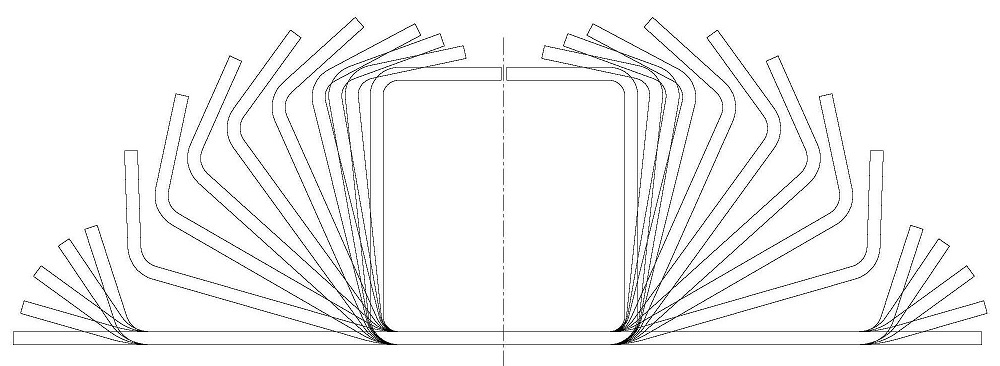

Square & Rectangle pipe mill is the special equipment to produce square and rectangle steel pipe. This equipment adopts the multipoint bending combined-type forming technology. One set of mould can produce all size of square and rectangle pipe. Compared with the traditional technology, the produce will have a good appearance, a good angle; share one set of mould, can cut down the cost of the machine, shorten the time of adjusting the mould; decrease the forming resistance, lighten the mould wear, reduce the load of power utilization.

Process Flow:

Raw Material (Strip Coil) ---- Decoiler ---- Snubber Roller + Pinch Roll + Leveler ---- Shear & Butt Welder ---- Horizontal Accumulator ---- Forming (directly forming to square to rectangle shape) ---- HF Welding ---- Scraping ---- Cooling ---- Sizing ---- Straightening ---- Cutting ---- Run-out